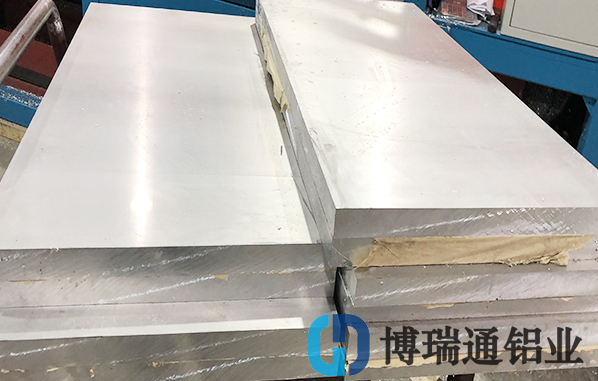

Today, 2A12 aluminum plate manufacturers want to introduce to you, 2A12 aluminum plate silver plating method.

The most important problem of silver plating on 2A12 aluminum plate and its alloy is the adhesion between coating and substrate metal.Therefore, it is necessary to take special treatment to obtain the silver coating with good bonding strength on 2A12 aluminum substrate.The method of dipping zinc can solve this difficulty well.

Zinc dipping is the use of 2A12 aluminum plate potential is more negative, in the electrolyte solution is easy to replace the principle of a thin layer of zinc replacement.The zinc layer is sandwiched between the base metal and the silver coating to enhance the bonding strength of the coating and the base metal.In the aluminum and its alloy silver plating process, but also pay attention to the following points:

Whether degreasing or alkali washing, the content of NaOH should not be too high, and the time should not be too long, so as to avoid surface corrosion.The process of zinc dipping is the key to obtain satisfactory coating.Dip zinc to two times, because after the first dip zinc, zinc layer is more rough.

After removing it with 1:1 HN0, the second zinc dipping is carried out. After the second zinc dipping, the next procedure can be entered only when the zinc layer is uniform and fine and has good binding force with the matrix.In the process of zinc dipping, attention should be paid to the swing to prevent parts from overlapping with each other and causing local zinc free layer.If the zinc dipping quality is not good, use 1:1 HN0, remove and then re-dipping zinc.The parts of 2A12 aluminum plate after deep processing and dipping zinc should be charged into the tank when entering the cyanide copper plating solution, and then return to the normal current after impacting the plating with high current for 2min.

The method of 2A12 aluminum plate silver plating is mentioned here. You can contact us if you need to know the price of 2A12 aluminum plate.