2A12 aluminum plate is generally used in the production of rolling process, that sometimes some customers will ask us whether we have cast rolled 2A12 aluminum plate, then today 2A12 aluminum plate manufacturers would like to talk to you, 2A12 aluminum plate hot rolling and casting rolling difference, I hope to help you.

The main difference lies in the different processing technology:

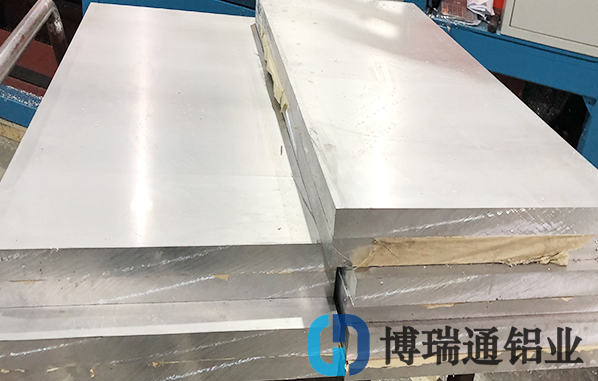

Hot rolling from aluminum ingot - melting and casting into flat ingot - milling - homogenizing annealing - hot rolling into strip

Cast-rolling is made of aluminum ingot - smelted - rolled into strips by a cast-rolling machine, with a lack of refinement in the middle.

We commonly use hot-rolled 2A12 aluminum plate, which is in the process of large plastic deformation, the internal structure is restored and recrystallized for many times, and the coarse grain is broken and the microcracks are healed in the casting state.

The cast-rolled 2A12 aluminum sheet is a semi-cast structure with strong crystallization direction.Compared with hot rolling, low cost, high efficiency but poor performance.

Usually, most customers choose hot rolled 2A12 aluminum plate.

The above is about the difference between hot rolling and casting rolling of 2A12 aluminum plate. If you want to consult the price of 2A12 aluminum plate, please contact us.