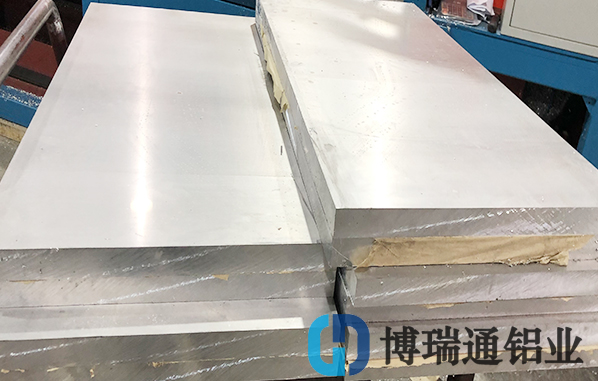

When 2A12 aluminum plate is produced, there may be grease on the surface. How is the grease generated?The following 2A12 aluminum plate manufacturers to elaborate.

The oil on the surface of 2A12 aluminum plate is mainly spread on the upper and lower part of the inlet and outlet of the extruder or at the roller neck. After being thrown and splashed, it drops on the surface of the box. Then, abnormal conditions are found in the roller cleaner of the extruder because of oil leakage from the thickness measurement head of the extruder, and the composition of this oil is disorderly and very dirty.

The thickness of 2A12 aluminum plate is relatively thin, and it is easy to produce foam during quenching afterwards. Moreover, because there is too much remaining oil on the surface, there will be a lot of residue on the surface of 2A12 aluminum plate, which will also cause the application performance in the middle and late period is not very good.On the other hand, if the appearance of 2A12 aluminum plate is sufficient and clean, it does not need to be processed, otherwise it will not be able to be used directly.

If it is the mechanical equipment itself will have a lot of oil stains, it should be cleaned up immediately.In addition, the surface of 2A12 aluminum plate should also be cleaned.

2A12 aluminum plate produces grease reasons and processing methods talk about this, need 2A12 aluminum plate can contact us.