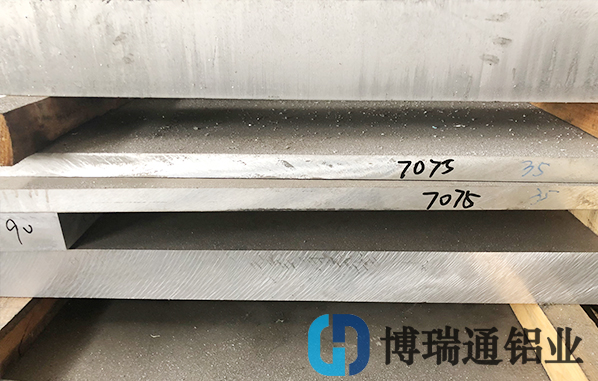

7075 aluminum plate is often used anodized, the following 7075 aluminum plate manufacturers say, 7075 aluminum plate anodized specific matters needing attention.

1, 7075 aluminum plate anodizing treatment temperature control at about 23℃ or below, the temperature is too high, cold sealing pore agent consumption, the surface layer "yellow".

2, 7075 aluminum plate immediately after anodizing treatment water cleaning, washing is not clean easy to lead to channeling liquid pollution, sealing tank will have loss.

3. The 7075 aluminum plate should be removed when it falls into the hole sealing groove, otherwise it will accelerate the increase of pH and the consumption of fluorine.

4, 7075 aluminum plate uses ammonium fluoride to adjust fluorine grouting reinforcement tank, each cubic should be inverted tank bottom cleaning once.

5, with hydrochloric acid fluoride grouting reinforcement tank, it is recommended to add in the way of 10% dilute solution, plus after 5 ~ 10 minutes.

6. It is strongly recommended to wash with 55±5℃ boiling water for 10 ~ 15 minutes, which can improve the quality of grouting reinforcement and accelerate the drying speed.

The above is not only about the specific matters needing attention of 7075 aluminum plate anodizing, want to know about the price of 7075 aluminum plate friends, welcome to inquire us.