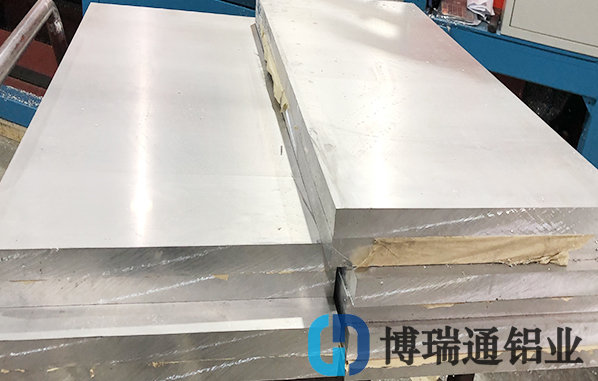

We all know that 2A12 aluminum plate is manufactured with the size of the whole plate, but customers usually need to be cut when they use it. Our common is sawing, and some customers will ask if they can use plasma cutting?Next 2A12 aluminum plate manufacturers to give you a solution.

The main advantages of plasma cutting are fast speed, clean edge after cutting, no need to deal with, provided that the plasma operation is correct.

Plasma cutting greatly reduces the bevel Angle on the cutting edge.If you want to weld non-square edges, you need a lot of trimming.This takes time to learn, and we can lead to problems with the business maintaining dimensional tolerances.So, this is because we know how to reduce the bevel.

Plasma cutting, like our welding method, uses an arc to generate a lot of heat.Unlike welding, no filler metal is added.Instead, the arc is fed with gas to produce an affecting plasma.The plasma melts, the gas melts and dissipates without trace, and the plasma nozzle is designed to rotate the gas into a vortex around the actual plasma used by the enterprise, which helps us prevent plasma drift.

It can be seen that 2A12 aluminum plate can be plasma cutting, but the premise is that the correct operation method is required. In addition, our company provides various specifications of 2A12 aluminum plate, if you need to contact us.