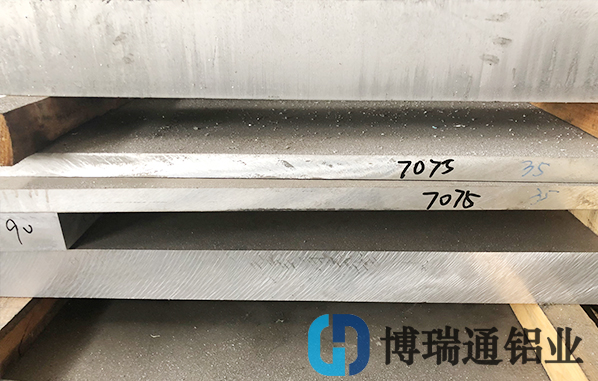

Today, 7075 aluminum plate manufacturers would like to introduce to you the reference basis of quenching heating speed of 7075 aluminum plate.

1. The high heating rate of 7075 aluminum plate can ensure that the whole process of work hardening is produced before the second phase melting, which is beneficial to improve the nucleation rate and get fine work hardening crystals, so rapid heating mode should be selected.

2. In order to improve productivity, rapid heating should be selected to reduce quenching time, save resources and improve productivity.

3. When the workpiece size of the heat treatment product is large and the amount of furnace is large, the heating rate is too fast. It may be opaque or asymmetrical, resulting in great internal stress, so the heating rate should be carried out.

4, in the very high strength 7075 aluminum plate selection of monoppole enhanced heat treatment tempering, heating rate, slow speed temperature, generally choose not higher than 60℃/h rate heating to 460~470℃, then change the temperature to 480℃ above, the goal is to make a low solution point AIZnMgCu phase all heat treatment tempering,At the same time, S phase can be better melted and coarse crystal can be avoided in metal materials.

The reference basis of 7075 aluminum plate quenching heating speed is this, want to know the price of 7075 aluminum plate can contact us.