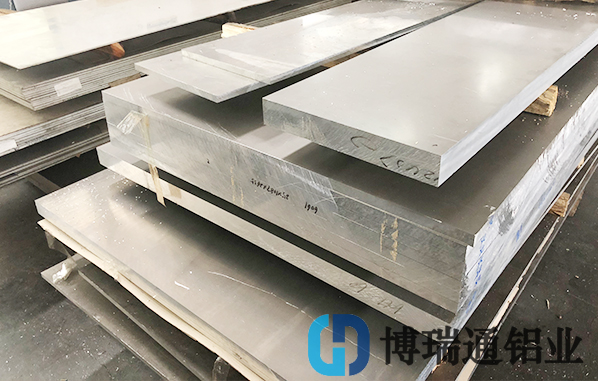

6061 aluminum plate is the material that needs to be heat treated. When 6061 aluminum plate is hot deformed, what factors will it be affected by?The following 6061 aluminum plate manufacturers to detail.

The thermal deformation conditions of 6061 aluminum plate include deformation temperature, deformation speed and thermal deformation.The same 6061 aluminum sheet material will have different effects in high temperature deformation heat treatment under different thermal deformation conditions.

The easier the dynamic recovery is, the less the energy storage in 6061 aluminum plate is, and the more difficult the recrystallization is. Therefore, increasing the deformation temperature is beneficial to high temperature deformation heat treatment.The faster the deformation rate of 6061 aluminum plate is, the more difficult the dislocation combination process is, which affects the composition of subgrains in the dynamic recovery process.

Therefore, in order to improve the effect of high temperature deformation heat treatment, the deformation rate should be reduced.In all conventional pressure processing methods, the speed of kneading deformation is relatively low, and it is easier to use kneading to achieve high temperature deformation heat treatment.Under the same deformation temperature and deformation speed conditions.

The larger the deformation degree is, the more the deformation storage is, which is beneficial to the recrystallization process, so it has an adverse effect on the high temperature deformation heat treatment.In short, in order to achieve high temperature deformation heat treatment, it is necessary to choose a reasonable thermal deformation process of 6061 aluminum plate.

6061 aluminum plate thermal deformation is about this, want to know the price of 6061 aluminum plate welcome to contact us.