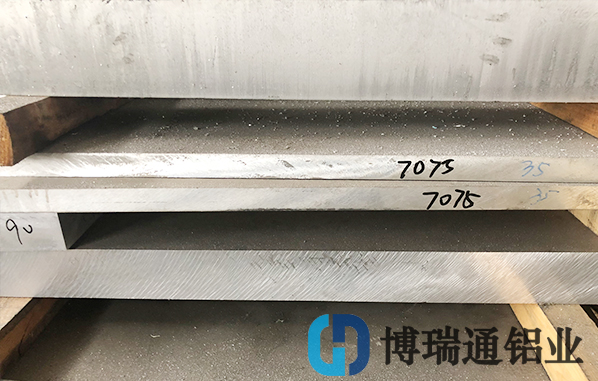

7075 aluminum plate in use is generally need to be cut, the cutting is not said to operate on the operation, but also need to have certain details, the next 7075 aluminum plate manufacturers to talk about, 7075 aluminum plate cutting details.

1. When the 7075 aluminum plate is framed, the end should be aligned, and the students on each layer should be separated by horizontal strips. The thickness of each horizontal strip should be consistent, and not significantly less than 4 strips.

2, cutting should keep the cutting saw table clean, do not allow a large number of aluminum chips, do not allow the 7075 aluminum plate overlapping cutting, so as not to scratch the surface of 7075 aluminum plate.

3, before cutting should check the surface quality and size of 7075 aluminum plate material, there will be a defect of 7075 aluminum plate to make an important mark, when cutting out these defects first, and then through the fixed size cutting.

4. When cutting, we shall not use the end cutting Angle more than 1.5°, and the deviation of the fixed length can be allowed to be +10mm.

5, put different density influence larger or thicker 7075 aluminum plate, the development between the layer equipment must have 50-100mm spacing.

6, before sawing 7075 aluminum plate, first determine the fixed length of 7075 aluminum plate product, check the approved size, and re-check the fixed length when cutting the first material.

7, in order to prevent the cutting saw blade heating, cutting should be lubricating oil cooling system and industrial aluminum processing technology equipment.

The above is about the details of 7075 aluminum plate cutting requirements, want to consult the price of 7075 aluminum plate can contact us.