The process of processing aluminum and aluminum alloys into rectangular sheets or rolls by smelting, ingot casting, various pre-rolling preparations, flat roll rolling, heat treatment and finishing.

1, aluminum and aluminum alloy plate and strip in hot-rolled state, annealing state, various levels of soft state and various heat treatment state supply.

2. Preparation before hot rolling mainly includes ingot quality inspection, soaking heat, sawing, milling, aluminum cladding and heating, etc.

3, the cooling rate of semi-continuous casting is very high, the diffusion process in the solid phase is difficult, and the ingot is easy to form chemical composition and uneven structure, such as incrystal segregation, so that the plasticity is reduced

4, the ingot surface segregation surface, slag inclusion, scar and crack defects, should be milling (see non-ferrous metal alloy ingot billet milling surface), this is an important factor to ensure good surface quality of finished products.

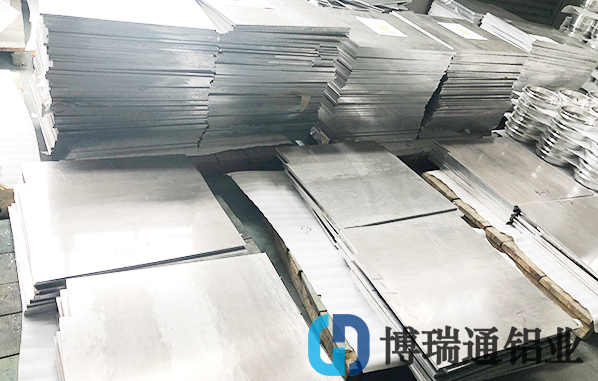

5, hot rolling: the hot rolling of aluminum alloy ingot is to provide blank for cold rolling, or directly produce hot rolled thick plate.

6. Hot rolling process includes pass reduction rate, rolling temperature, rolling speed and lubrication cooling, etc.